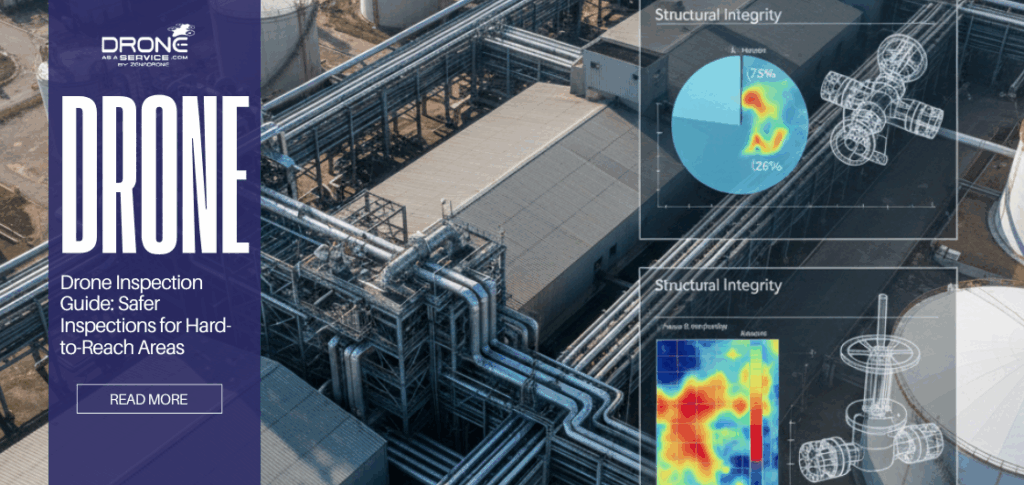

Drone Inspection Guide: Safer Inspections for Hard-to-Reach Areas

Introduction

Drone inspection has transformed how industries inspect assets that are difficult, dangerous, or costly to access. From rooftops and power lines to industrial facilities and critical infrastructure, drones now make it possible to inspect assets safely, quickly, and with minimal disruption. Instead of sending people into risky environments, organizations can collect high-quality inspection data from the air or confined spaces.

This guide explains everything you need to know about drone inspection. You’ll learn what drone inspection is, how it evolved, where it’s used, the benefits it delivers, legal considerations in the United States, how to choose the right inspection drone, cost factors, and what the future of drone inspection looks like. By the end, you’ll understand why drone inspection is becoming the new standard across industries.

Let’s start with the fundamentals before going deeper.

What Is Drone Inspection?

Drone inspection is the use of unmanned aerial vehicles (UAVs) equipped with cameras and sensors to inspect structures, assets, and infrastructure. These drones capture visual, thermal, and spatial data that helps identify damage, defects, heat loss, or structural issues without direct human access.

Drone inspection is commonly used for condition monitoring, preventive maintenance, safety assessments, and post-event evaluations such as storm or accident damage.

Understanding what drone inspection is makes it easier to see why it’s replacing traditional methods.

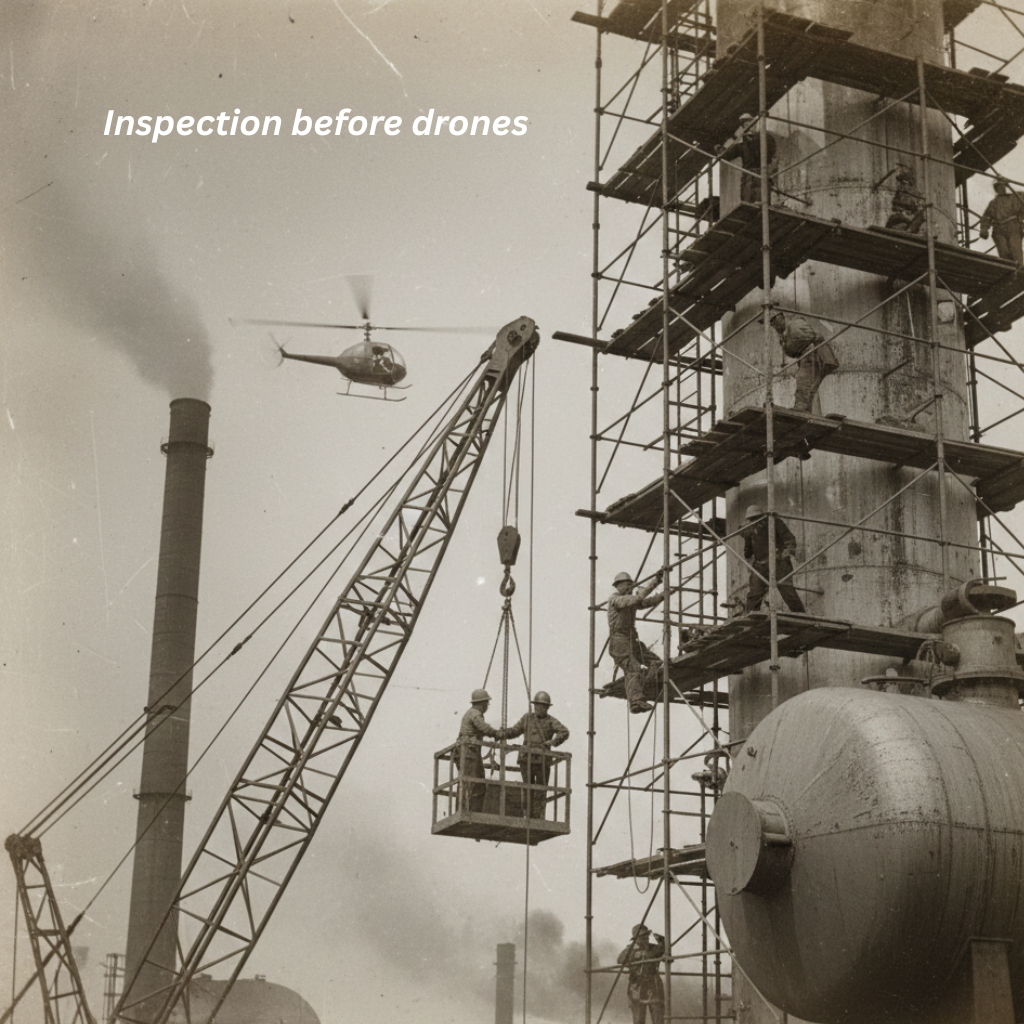

A Brief History of Inspections Before Drones

Before drones, inspections relied heavily on manual methods. Inspectors used scaffolding, rope access, cranes, lifts, or even helicopters to reach elevated or hazardous areas. These approaches were time-consuming, expensive, and exposed workers to significant safety risks.

In many cases, operations had to be shut down to allow inspections, increasing downtime and costs. These challenges created a clear need for a safer, more efficient inspection method paving the way for drone inspection.

Drone inspection emerged as a response to these limitations offering access without exposure. This shift set the stage for the evolution of inspection technology.

Evolution of Drone Inspection Technology

Drone inspection did not emerge fully formed. Early drones were limited to basic visual inspections using standard cameras and manual flight control. Their role was largely observational.

As technology advanced, improved GPS accuracy, stabilization systems, and autonomous flight modes made inspections more consistent and repeatable. Inspectors could now capture data from the same angles over time, enabling better condition tracking.

The introduction of advanced sensors marked a major shift. Thermal cameras revealed heat anomalies invisible to the naked eye, LiDAR enabled precise 3D modeling, and AI-powered analytics began identifying defects automatically. Today, drone inspection is less about flying and more about intelligent data collection and analysis.

How Drone Inspection Works (End-to-End Process)

Drone inspection follows a structured workflow:

- Inspection planning and risk assessment

- Selecting the appropriate drone and sensor

- Executing the flight mission

- Capturing visual, thermal, or spatial data

- Processing and analyzing the data

- Delivering actionable inspection reports

Each step ensures inspections are accurate, repeatable, and compliant. The process matters as much as the technology.

Types of Inspection Drones

Different inspection environments require different drone platforms.

Multi-rotor drones

Multi-rotor drones are ideal for close-range inspections of buildings, roofs, towers, and vertical structures.

Fixed-wing drones

Fixed-wing drones are used for long-range inspections such as pipelines, rail corridors, and large infrastructure.

Indoor and confined-space drones

Indoor and confined-space drones are designed for GPS-denied environments like warehouses, tanks, and industrial interiors.

Selecting the right drone is critical to inspection success.

If you like to explore this section more, you may read here: What Is a Drone Service?

Inspection Sensors Explained

Inspection drones rely on sensors to capture meaningful data.

- RGB cameras provide high-resolution visual imagery for surface inspection and documentation.

- Thermal drone inspection uses infrared sensors to detect heat loss, electrical faults, and insulation problems.

- LiDAR sensors create accurate 3D models for measurements and structural analysis.

The right sensor depends on the inspection objective, not just the drone platform.

Industries Using Drone Inspection

Powerline and Utility Inspections

Powerline inspection drones safely inspect live electrical assets, reducing outage risks and improving maintenance planning.

Roof and Building Inspections

Drone roof inspections enable fast damage assessments without ladders, lifts, or safety hazards.

Infrastructure Inspections

Bridges, towers, pipelines, and roads benefit from aerial drone inspection by identifying issues early.

Industrial and Energy Inspections

Wind turbines, solar farms, and oil & gas facilities use drones to minimize downtime and improve worker safety.

One technology now supports many industries with the same core goal: safe access and reliable data.

Benefits of Drone Inspection

Drone inspection significantly improves safety by removing people from hazardous environments. It reduces costs by eliminating heavy access equipment and minimizing operational downtime. Inspections are completed faster, often in hours instead of days.

Let’s discuss drone inspection benefits in detail one-by-one:

- Enhanced Safety

Drones can access hazardous, hard-to-reach, or dangerous areas without putting human lives at risk. For example:

- Inspecting tall towers, bridges, wind turbines, or industrial chimneys.

- Entering confined spaces or areas with toxic gases.

- Humans don’t have to climb, use scaffolding, or operate heavy machinery in risky environments.

- Cost Reduction

Traditional inspections often require cranes, scaffolding, or specialized equipment. Drones eliminate much of this need, which:

- Cuts labor costs.

- Reduces equipment rental expenses.

- Minimizes operational downtime because inspections are quicker and less disruptive.

- Faster Inspections

Drones can cover large areas in a fraction of the time compared to manual inspections. For example:

- Roofs or pipelines that take days to inspect manually can be scanned in hours.

- Rapid data collection allows teams to act faster on maintenance decisions.

- Superior Data Quality

Drones can carry advanced sensors like high-resolution cameras, thermal imaging, LiDAR, and multispectral sensors. This results in:

- Detailed visual records.

- Thermal maps to detect heat leaks, electrical faults, or water intrusion.

- Accurate 3D models for planning and analysis.

- Repeatability and Objectivity

Drone inspections create consistent and standardized data, which makes monitoring over time easier:

- Comparisons between past and current inspections highlight changes.

- Reduces human error in data collection and analysis.

- Accessibility and Flexibility

Drones can quickly reach areas that are difficult for humans or vehicles to access, such as:

- Remote locations.

- Complex industrial structures.

- Large agricultural fields or solar farms.

- Environmental Benefits

Using drones reduces the need for heavy machinery and vehicle use, lowering carbon footprint and minimizing disruption to surrounding areas.

Drone Inspection vs Traditional Inspection Methods

Traditional inspections are labor-intensive, risky, and slow. Drone inspections offer a safer and more efficient alternative with better data quality and minimal disruption.

Comparison Table

|

Factor |

Traditional Inspection |

Drone Inspection |

|

Safety |

High human risk |

Minimal human exposure |

|

Access |

Limited and complex |

Easy access to hard-to-reach areas |

|

Time |

Days or weeks |

Hours or days |

|

Cost |

High equipment and labor costs |

Lower operational costs |

|

Data Quality |

Manual and subjective |

High-resolution and repeatable |

|

Downtime |

Often required |

Minimal or none |

|

Scalability |

Difficult |

Highly scalable |

Legal and Regulatory Considerations (US Focus)

Regulatory compliance isn’t just bureaucracy, it’s the foundation that makes professional drone inspection safe, standardized, and legally enforceable. In the U.S., the Federal Aviation Administration (FAA) regulates commercial drone use under 14 CFR Part 107, with additional authorizations and waivers needed for advanced operations.

FAA Part 107 – The Core Rulebook for Commercial Drone Use

Part 107 applies to small drones (under 55 lbs) used for business purposes, including infrastructure, energy, agriculture, real estate, and inspection work.

Under Part 107:

- You must operate the drone within visual line of sight (VLOS) meaning the pilot or an observer can see the drone without optical aids (except corrective lenses).

- Remote pilots need an FAA Remote Pilot Certificate after passing the FAA’s knowledge test.

- Drones must be registered with the FAA and carry their registration number.

- You must avoid careless/reckless operations and yield right‑of‑way to manned aircraft.

Part 107 includes limits on altitude, flight conditions, and where you can fly and compliance is mandatory for commercial use.

Penalties for Non‑Compliance

Not following FAA rules isn’t just risky, it’s legally punishable. Although specifics vary, consequences may include civil fines, criminal penalties, and loss of your Remote Pilot Certificate if violations are serious.

Why Do These Regulations Matter?

Compliance with FAA rules ensures that drone inspections:

- Are legally valid and defensible in contracts or insurance claims.

- Maintain airspace safety by preventing conflicts with manned aircraft and unsafe flights.

- Operate with clear standards, so data collected (photos, maps, models) is produced responsibly and consistently.

These rules make the commercial use of drones not just safe for pilots and workers, but also compatible with the broader aviation ecosystem.

Best Drones for Inspections

The best drone for inspections depends on the task and environment. Outdoor industrial inspections require stability, payload capacity, and endurance. Indoor inspections prioritize compact size and obstacle avoidance. Surveying and mapping demand longer flight times and advanced sensors.

There is no single “best” inspection drone, only the best drone for a specific inspection need.

Cost Factors of Drone Inspection Services

Drone inspection costs vary based on asset type, location, sensors used, data processing requirements, and reporting depth. While upfront costs may vary, drone inspections often deliver long-term savings by reducing downtime, improving safety, and enabling better maintenance decisions. Value should be measured beyond the initial price.

The Future of Drone Inspection

More Autonomy, Less Manual Control

Right now, most professional inspections still involve a remote pilot controlling the drone. In the future, drones will increasingly fly autonomously , meaning they plan and execute inspection routes with minimal human input. Advances in onboard navigation systems, GPS precision, and sensor fusion allow drones to:- Automatically adjust flight paths based on obstacles, structure geometry, and mission goals.

- Return to charging stations or swap batteries without a human present.

- Fly repeatable inspection routes that maximize coverage and minimize risk.

AI-Driven Defect Detection and Decision Support

The real leap forward comes from machine intelligence. Modern drones don’t just capture data; they’re beginning to understand what they capture. AI and machine learning models can analyze imagery and sensor data to spot anomalies that human inspectors might miss, such as:- Tiny cracks or material fatigue in structural elements.

- Thermal anomalies in electrical systems indicating insulation breakdown or overload.

- Progressive corrosion patterns that hint at future failure.

Predictive Maintenance Instead of Reactive Fixes

Today’s inspections are mostly reactive: you check something, find a problem, and fix it. Tomorrow’s will be predictive. By combining historical inspection data with pattern recognition and trend analysis, systems can forecast where failures are likely to occur before they happen. This shift toward predictive maintenance means:- Organizations schedule service based on risk and lifecycle modeling, not calendar dates.

- Unexpected failures and the costs and downtime that come with them are dramatically reduced.

- Budgets are spent more efficiently, targeting true need instead of routine checks.

Integration with Digital Twins

A digital twin is a dynamic, virtual replica of a physical asset. As drone data gets continuously fed into such models, the twin stays up‑to‑date, capturing both geometry and condition over time. With robust digital twin integration:- Teams can simulate stress, wear, damage propagation, or environmental effects in a virtual environment.

- Remote teams can inspect or analyze assets without traveling to the site.

- Maintenance plans can be visually mapped and tested before execution.

Why This Matters for Asset Management

As these technologies mature, drone inspection becomes integral to how organizations manage and sustain physical assets. It’s not just about seeing a crack, it’s about integrating that insight into business decisions, risk management, and long‑term planning. Companies that adopt these future capabilities early will see tangible benefits:- fewer unexpected breakdowns,

- optimized maintenance scheduling,

- longer life for infrastructure,

- and better ROI from both drones and the assets they monitor.

Why Consider Drone as a Service (DaaS)?

Drone as a Service (DaaS) provides access to professional drone inspection capabilities without the need to purchase hardware, hire pilots, or manage compliance. It allows organizations to scale inspections easily and choose the right drone for each task.

DaaS delivers end-to-end inspection solutions from planning to reporting with minimal operational burden.

Inspection-Ready Drones from ZenaDrone DaaS

DaaS mother company ZenaDrone, offers specialized drones designed to meet different inspection requirements:

ZenaDrone 1000

A powerful platform suited for large-scale industrial and outdoor inspections.

IQ Square

A mid-range, AI-enabled drone designed for inspection and surveying applications.

IQ Nano

A compact drone built specifically for indoor and confined-space inspections.

IQ Quad

Optimized for precision mapping and surveying with extended flight performance.

These options allow organizations to select inspection drones based on operational needs and environments.

Frequently Asked Questions About Drone Inspection

What is drone inspection used for?

Drone inspection is used to inspect roofs, power lines, buildings, infrastructure, and industrial assets that are difficult or unsafe to access manually. It helps identify damage, faults, heat loss, and structural issues using aerial and sensor-based data.

Are drone inspections safe?

Yes. Drone inspections significantly reduce human exposure to hazardous environments such as heights, confined spaces, and live electrical infrastructure. Safety is one of the primary reasons organizations adopt drone inspection.

Do drone inspections require FAA approval in the US?

Drone inspections in the US must comply with FAA Part 107 regulations. A certified remote pilot is required, and operations must follow airspace and safety rules. Advanced missions like BVLOS may require additional authorization.

What industries benefit most from drone inspection?

Industries such as utilities, construction, infrastructure, energy, oil & gas, insurance, and property management benefit most from drone inspection due to safety, efficiency, and data quality improvements.

What is the best drone for inspections?

There is no single best drone for inspections. The right choice depends on the inspection environment, payload requirements, sensors, and whether the inspection is indoor or outdoor.

How much does a drone inspection cost?

Costs vary based on asset type, location, sensors used, and reporting requirements. While pricing differs, drone inspections often cost less than traditional inspections when safety, downtime, and access equipment are considered.

What data do drone inspections provide?

Drone inspections typically deliver high-resolution images, thermal maps, 3D models, and inspection reports that support maintenance and decision-making.

Conclusion: Why Drone Inspection Is the New Standard

Drone inspection has evolved from an emerging technology into an industry standard. It delivers safer operations, better data, and greater efficiency across sectors. As autonomy and intelligence continue to advance, drone inspection will play an even greater role in infrastructure monitoring and asset management.

Inspection has changed, and it’s not going back.

Read Our Other Blogs

23 January 2026

Aerial Data Collection: How Drones Are Transforming Data Capture and Analysis

Aerial Data Collection: How Drones Are Transforming Data Capture and Analysis Introduction: When Data Needs a Higher Perspective When data...

21 January 2026

Drone Inspection Guide: Safer Inspections for Hard-to-Reach Areas

Drone Inspection Guide: Safer Inspections for Hard-to-Reach Areas Introduction Drone inspection has transformed how industries inspect assets that are difficult,...

21 January 2026

PPK Workflow for Drones: Complete Process & Accuracy

PPK Workflow for Drones: Complete Process & Accuracy Drone operators aren’t the only ones concerned with accuracy for any project....

20 January 2026

Altitude Hold Technology in Drones: Stability, Control, and Flight

Altitude Hold Technology in Drones: Stability & Control Before technological developments, drones were viewed as niche gadgets. Today, it is...

20 January 2026

Autonomous Drones: Technology, Applications, and Advanced Solutions

Autonomous Drones: Technology, Applications, and Advanced Solutions Introduction Autonomous drones are rapidly reshaping how industries collect data, monitor assets, and...

19 January 2026

Drone Beyond Visual Line of Sight (BVLOS)

Drone Beyond Visual Line of Sight (BVLOS) Remember the last time you flew a drone? You probably had to keep...