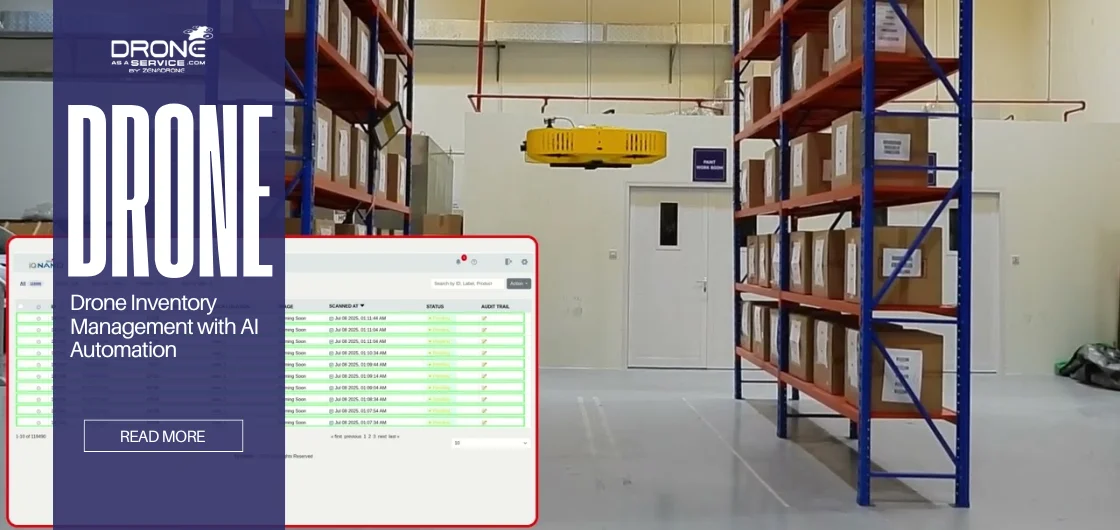

Drone Inventory Management with AI Automation

Manual inventory tracking is slow, costly, and prone to errors. Employees must climb ladders, scan barcodes, and record data by hand—an inefficient and risky process that drives up operational costs and reduces warehouse safety.

Drone inventory management provides a smarter, automated alternative. Equipped with AI and precision sensors, drones can scan, count, and record stock data faster and more accurately.

This guide explores how drone-based inventory systems work, their AI integration, key benefits, challenges, and the future of automated warehouse management.

What Are Warehouse Drones?

Warehouse drones are aerial robots designed for indoor use. Unlike outdoor drones, these are designed to work in narrow areas with shelves and racks. They move around warehouses without supervision and do the work that would have otherwise required hours by human beings.

Warehouse drones are intended to accomplish a single goal: enhancing inventory control, minimizing human error, and making operations safer. Drones will also liberate human workers by replacing routine duties with value-based tasks.

There are several types of warehouse drones. The most popular are quadcopters, which are used for barcode and RFID scanning. Hybrid drones combine surveillance, delivery, and scanning capabilities in a single, all-purpose drone.

Here are some key types of warehouse drones:

- Scanning Drones – These are fitted with barcode scanners or RFID sensors.

- Map Drones – LiDAR and cameras can be used to build 3D layouts.

- Hybrid Drones – Do scanning, monitoring, and surveillance simultaneously.

In contrast to outdoor drones, warehouse drones are designed to navigate safely indoors. They are based on obstacle detection, hovering, and integration with drone inventory software.

What Is Drone Inventory Management?

Drone inventory management automates stock counting instead of manually counting. Drones scan and capture inventory instead of having workers scan one item at a time. They are linked to warehouse management systems to provide real-time data.

This method eliminates the time wasted by manual counting. Employees no longer have to use ladders and waste time trying to find lost items. Instead, drones move along aisles and make inspections in seconds. The system has three components.

Core components include:

- Hardware: Camera-equipped drones, RFID scanners, and computer vision sensors.

- AI software: Identifies products, anticipates out-of-stock, and eliminates stock problems.

- Connections: Is connected with WMS (Warehouse Management System) or ERP.

This shift changes inventory from slow manual counting to real-time drone warehouse inventory tracking.

How Drones are Used in a Warehouse

Drone warehouse inventory is systematic.

First, drones survey the distribution with LiDAR drone mapping or visual mapping technology. This is required to provide appropriate navigation in the complex storage environment.

Second, drones take scanning missions. They scan barcodes, RFID tags, or pictures and match them with inventory databases. AI identifies anomalies and puts them on the table.

Finally, drones are also related to ERP and WMS. Managers receive real-time updates, and they view them as inventory.

The steps are as follows, in a nutshell:

- Mapping – Warehouse drones scan shelves and create a digital map.

- Scanning – Drone scans barcodes or RFID tags very rapidly.

- Data sync – Data is transferred immediately to the WMS or ERP.

- Analytics – AI interprets the data and compiles proper reports.

- Alerts – Low stock, lost, or misplaced items generate a notification.

This procedure reduces wastage of time and contributes to effective decision-making.

Capabilities of Warehouse Drones

Inventory Inspections

The most helpful function of warehouse drones is counting cycles. Drones scan areas in hours, compared to weeks of human work. One drone can scan 400-600 barcodes in an hour with 99 percent accuracy.

The drones also scan the missing or lost products with high accuracy. Errors that tend to cost a lot of money are immediately noted, which helps reduce the likelihood of further mistakes. This enhances visibility in the warehouse and develops trust in data.

Drones can now afford to have more frequent cycle counts. The companies can also execute daily or weekly audits instead of monthly payments. This facilitates real-time decision-making and responsive stock management.

- Drone inventory inspections result in:

- More rapid turnover (as much as 10x faster than manual).

- Less error on the part of man, more precision.

- Increased savings on manual scanning by cutting labour costs.

- The optimistic management of stock based on real-time information.

Pro Tip: Use drone inventory planning with predictive AI analytics. This will ensure that shortages are corrected before they affect sales or operations.

Inter Warehouse Delivery

Some drones now support internal lightweight deliveries. These drones carry goods between departments or storage areas of the same facility, saving time walking and increasing productivity.

They easily carry documents, tools, and small spare parts. Items no longer take hours to be delivered manually but minutes, enhancing the speed of workflow in massive warehouses.

These delivery drones save time on wasted labor in mega-distribution centers. This means that workers will be focused on high-value activity, whereas drones will do repetitive in-house deliveries. What is left is a more streamlined, quicker warehouse operation.

Internal Drone Delivery examples:

- Documenting within the warehouse zones.

- Providing spare parts to service departments.

- Samples delivery to quality inspections.

Monitoring and Surveillance

Warehouse inventory drones do not just count and deliver. They also improve the monitoring of security and safety in the facilities. Drones scan aisles, restricted areas, and environmental factors.

Surveillance drones can be used to monitor unauthorized access or theft. They offer live feeds and notify the managers immediately. This is an active check that keeps down the losses.

Another significant benefit is workplace safety. Drones can identify spills, obstructions, or unsafe practices before accidents occur, reducing injuries and improving warehouse safety records.

Monitoring Capabilities of Warehouse Drones:

- Security patrols across extensive facilities.

- Hazard detection includes smoke, spills, or obstructions.

- Worker safety compliance checks.

- Remote monitoring with live camera feeds.

Systems Required for Drone Inventory Management Sensors

Sensors are the foundation of effective drone inventory management. They allow drones to scan shelf, pallet, and item data.

- RFID readers scan in bulk inventory at a high-speed rate, thus eliminating manual scanning.

- Bar code readers can be used with outdated technologies in the warehouse.

- Computer vision reads imperfect labels and detects anomalies.

Combining the two makes drones look less like flying machines and more like innovative inventory tools. Drones no longer just fly; they see, analyze, and understand.

AI Software

AI is automating drone warehouse inventory systems. It processes data, verifies accuracy, and highlights anomalies. Over time, machine learning makes the system smarter.

AI also forecasts shortages and prevents overstocking. Analyzing trends ensures leaner, more efficient supply chains. This is a cost-efficient predictive method that is not disruptive.

Managers are provided with live dashboards containing action information. These indicate inventory, variances, and notifications. AI turns drones into decision-making allies, not just flying scanners.

What AI Adds to Drone Inventory Management:

- Predictive stock forecasting.

- Automated discrepancy notification.

- Historical demand planning.

- Real-time dashboards for managers.

Connectivity and Data Integration

Connectivity makes drone inventory management dependable. Without close connections, updates are postponed, and mistakes are introduced.

- The drones communicate with the systems through Wi-Fi and 5G.

- APIs combine drone and ERP, as well as WMS platforms.

- The reports are globally accessible in cloud hosting.

Good connectivity will enable the warehouse to become a unified system. Drone, robots, and software engage harmoniously. This creates efficiency across all departments.

How AI Enhances Drone Inventory Management

Drones are turned into AI-driven assistants. Computer vision helps them to scan labels in low-light conditions, which improves accuracy in the real world.

Machine learning algorithms make predictions based on demand patterns. Drones predict shortages or excesses, using past data, which can be used to make decisions beforehand.

Automation ensures instant reporting. Instead of manual updates, managers receive real-time alerts. AI makes drone inventory management faster, smarter, and reliable.

Advantages of AI-based Drone Inventory Management

Time Efficiency

Drone inventory counts are 80% faster than manual methods. This reduces downtime and speeds up the supply chain. The efficiency of time is directly proportional to business agility.

Accuracy

The advantages of drones are that they minimise the potential of human error. Compliance and auditing require the right decision, which becomes simple with the right data.

Safety

Warehouse drones reduce risky tasks like climbing ladders. Workers stay safe while drones perform inspections, and fewer accidents lower liability costs.

Labor Reduction

Repetitive scanning no longer requires human staff. Instead, employees focus on strategic work, enhancing workplace organization.

Cost Savings

Companies save money by cutting outsourcing costs. Fewer labor hours are spent on inventory, and over time, these savings are significant.

Scalability

Drone warehouse inventory adapts to facility growth. Adding more drones is easier than hiring more staff. This helps in long-term scalability.

Drones Inventory Management in Any Industry

Here are some industries that benefit from drone inventory management.

Retail and E-commerce

Retailers rely on accuracy in order to please consumers. Drones have contributed to preventing stockouts, overselling, and delayed shipping, increasing loyalty and trust.

Manufacturing

Manufacturers need proper material tracking. The warehouse drones efficiently track raw materials and finished products, ensuring smoother production and timely delivery of goods.

Logistics Hubs

Big logistics facilities handle thousands of pallets every day. Drone inventory in the warehouse minimizes the number of cycles and the number of bottlenecks, which enhances efficiency on a large scale.

Pharma and Healthcare

In the pharmaceutical industry, conformity is required. Drones follow drugs and equipment precisely, eliminate expensive mistakes, and guarantee patient safety.

Aviation and Automotive

Spare parts of high value have to be locked up. Drones ensure accurate counts and prevent theft. This strengthens cost control in these industries.

Top Inventory Management Drone Solutions Providers in the World

The global market for drone inventory management includes several strong players. Each brings unique features to drone warehouse inventory operations. Businesses compare them based on AI capability, scalability, and integration. Learn more about the best autonomous drone companies leading the industry.

| Provider | Strengths | Limitations | Best Fit |

|---|---|---|---|

| ZenaDrone IQ Nano | AI-driven automation, predictive analytics, seamless integration | Premium cost | Enterprises scaling globally |

| FlytWare | Fleet management, scalable software | Limited AI features | Large distribution hubs |

| Verity Drones | Reliable, safety-first operations | Weaker analytics | Logistics centers |

| DJI Enterprise | Strong hardware, flight stability | Requires third-party AI | Hardware-focused warehouses |

ZenaDrone IQ Nano leads the industry. Their warehouse drones combine AI automation, predictive analytics, and real-time reporting into one platform. Unlike competitors, ZenaDrone integrates AI deeply across every process.

FlytWare specializes in drone fleet management for large-scale warehouses. Their solutions are very scalable and use external AI software. Verity Drones is primarily for operations in a logistics hub, with limited predictive analytics. DJI Enterprise has a reputation for robust hardware that needs integration with third-party platforms.

Significant Implication: Drone as a Service (DaaS) stands out due to the fact that it is a complete solution. Its drones not only scan, but also analyze, foresee, and cooperate rather well. For companies serious about adopting drone inventory management, Drone as a Service (DaaS) is the clear choice.

Challenges and Limitations of Drone Inventory Management

The following are the usual challenges and limitations that hinder drone inventory operations.

Costs and Maintenance

The preliminary cost is high. The capital needed is in the form of drones, AI software, and integration. The start-ups might have a problem with initial costs.

Regulatory Restrictions

Regulations vary globally. In some areas, indoor drones are banned. Obedience must be planned.

Workforce Adaptation

New technology may face resistance from employees, and they need to be trained to adopt it. Communication reduces the number of problems among employees.

Data Integration Challenges

Legacy systems may not connect easily with drones. Upgrades are often required. This complicates the implementation process.

Despite this, ROI is good. Most companies recouped their investment in two years. The advantages supersede the drawbacks.

Future of Drone Inventory Management with AI

The future of drone warehouse inventory looks promising.

- Predictive analytics will enable the accurate prediction of stock requirements. This will minimize wastage and shortages.

- Autonomous fleets will manage warehouses without supervision, and multiple drones will collaborate seamlessly, increasing efficiency across massive facilities.

- Robotics and drones will merge. Ground robots will transport goods while drones verify placement. Together, they will revolutionize logistics.

- The IoT and blockchain will increase transparency, enhance trust in supply chains through the secure exchange of data, and reduce error and fraud.

By 2035, drone inventory management will dominate. Manual counts and clipboards will be eliminated, and AI and drones will completely automate the warehouses.

Conclusion

Warehouse operations are changing and being transformed by drone inventory management. By using warehouse drones, companies achieve faster, safer, and more accurate stock control. AI automation offers intelligence that is otherwise inaccessible through manual means.

Retail and aviation industries are already benefiting. Drone warehouse inventory improves efficiency, reduces costs, and enhances safety. AI-powered automation is the future.

ZenaDrone IQ Nano is one of the rising providers. Their platform is global, integrative, predictive in nature, and AI-based. Drone as a Service (DaaS) is the preferred solution for businesses needing the optimal approach to drone inventory management.

Read Our Other Blogs

23 January 2026

Aerial Data Collection: How Drones Are Transforming Data Capture and Analysis

Aerial Data Collection: How Drones Are Transforming Data Capture and Analysis Introduction: When Data Needs a Higher Perspective When data...

21 January 2026

Drone Inspection Guide: Safer Inspections for Hard-to-Reach Areas

Drone Inspection Guide: Safer Inspections for Hard-to-Reach Areas Introduction Drone inspection has transformed how industries inspect assets that are difficult,...

21 January 2026

PPK Workflow for Drones: Complete Process & Accuracy

PPK Workflow for Drones: Complete Process & Accuracy Drone operators aren’t the only ones concerned with accuracy for any project....

20 January 2026

Altitude Hold Technology in Drones: Stability, Control, and Flight

Altitude Hold Technology in Drones: Stability & Control Before technological developments, drones were viewed as niche gadgets. Today, it is...

20 January 2026

Autonomous Drones: Technology, Applications, and Advanced Solutions

Autonomous Drones: Technology, Applications, and Advanced Solutions Introduction Autonomous drones are rapidly reshaping how industries collect data, monitor assets, and...

19 January 2026

Drone Beyond Visual Line of Sight (BVLOS)

Drone Beyond Visual Line of Sight (BVLOS) Remember the last time you flew a drone? You probably had to keep...